Consulting Services

The start of the implementation of a new ERP and MES application is a good time to to review your current business and production processes and to realize time and cost-cutting potentials. As we have accompanied more than a hundred successful implementations over our thirty years of company history, our employees have a rich experience of the specific needs of textile manufacturers and their processes.

High Degree of Specialization

As our software solution is tailored specifically to the needs of customers in the textile industry, we have a high degree of specialization and the corresponding niche knowledge regarding the textile industry .

International

Team

Our international team of full time employed consultants distributed worldwide in our subsidiary offices in six countries on three continents. Our consultants have their backgrounds in textile engineering or in business administration.

Best Practice

Experience

In our thirty years of company history we have consulted dozens of textile companies from all around the world. Our team therefore has a unique pool of best practice experience for textile processes.

Production Process Knowledge

Niche know-how for specific solutions in particular businesses such as spinning, weaving, yarn / fabric dyeing, commission dyeing, printing and finishing, vertical integrated mills or other business types

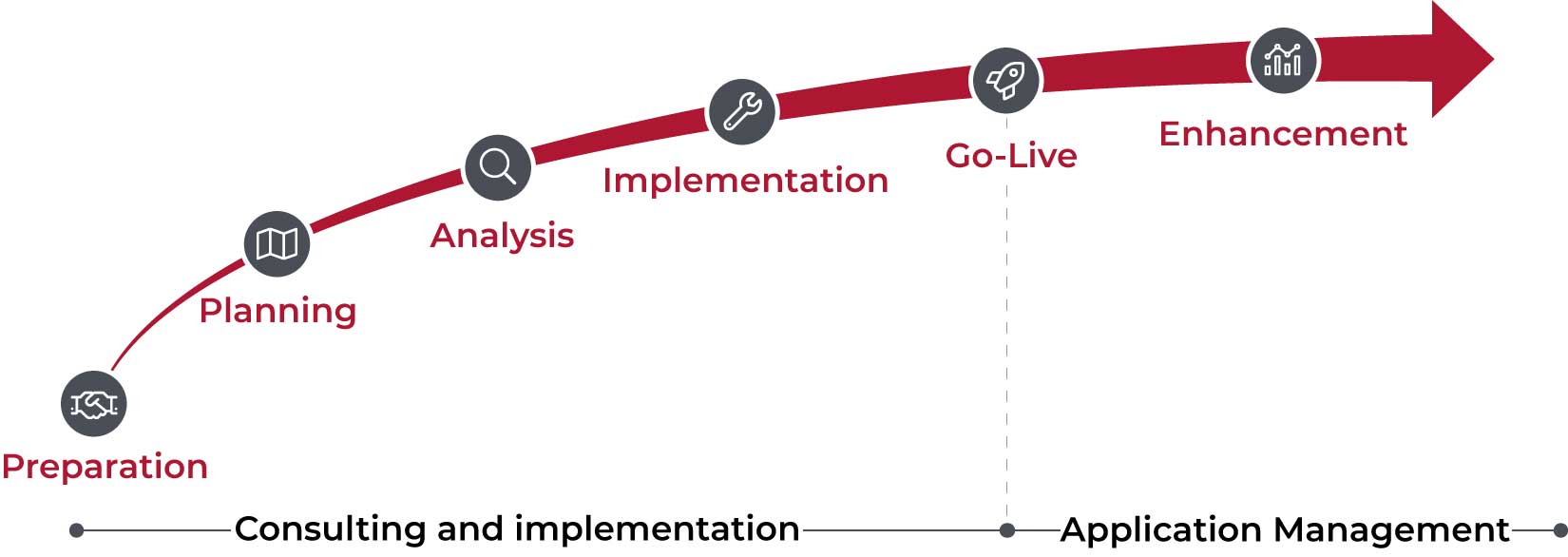

Implementation

In opposite to most investments the ERP implementation affects nearly all departments of the business. From Production to Sales and Purchasing, Warehouse management also the processes are analysed, challenged and reworked. It is the perfect opportunity to turn the organisation updside down mentally and define a modern and future-oriented structure. Accordingly this big change to the whole business must carefully planned. There is a vast number of possibilities going step wis or live at once. Therefore right after the preparation and deep understanding of the business the planning phase is the beginning of it and of high importance.

1. Preparation Phase

Individual requirement assessment, broad analysis of key challenges to be optimized by ERP implementation, system landscape design as is and to be, demonstration of solutions to the individual business requirements, optional RFP processing

2. Planning Phase

It is the most important phase of project before execution commences. For the success of the project, it must be known and planned in advance who will do what, with whom, where, when, at what timeline, to address which problems. As a result, this phase helps develop a realistic and clear plan for the entire project which includes scheduling and timeline of project, identification of roles and responsibilities for the Intex project implementation. In all practical purposes, this phase provides the direction of project execution.

3. Analysis Phase

This essentially sets tone for the entire project execution as it helps identify the core quality requirements (fits) and developments (gaps). Other objectives are to identify optimizing potentials, business processes re-engineering, data migration strategies, and development designs which further provide guideline for implementation.

4. Implementation Phase

Implementation phase fulfills project execution according to the strategy as designed in planning phase such phase-wise, big-bang rollout, etc. It involves tasks such as system parameterization, configurations, interfaces, system testing, key-user training (with train the trainer principle).

5. Go-Live

To proactively achieve data migration preparation and execution, end-user training, integration tests, cut-over from existing software landscape to Intex ERP.

6. Enhancement Phase

Nice-to-have and other developments with secondary priority which are identified during Analysis Phase and later on during project execution phases can be implemented in enhancement phase. This helps achieve further stabilize the implementation.